Gartner Unveils Top Supply Chain Technology Trends for 2024

Leaders in the supply chain sector are constantly looking for new ways to enhance efficiency and, ultimately, drive better business outcomes.

Thankfully, according to Gartner, supply chain tech leaders and CSCOs are set to benefit from numerous exciting advancements in technology, providing them with opportunities to support new business models, augment and automate decision making, and foster ecosystem collaboration.

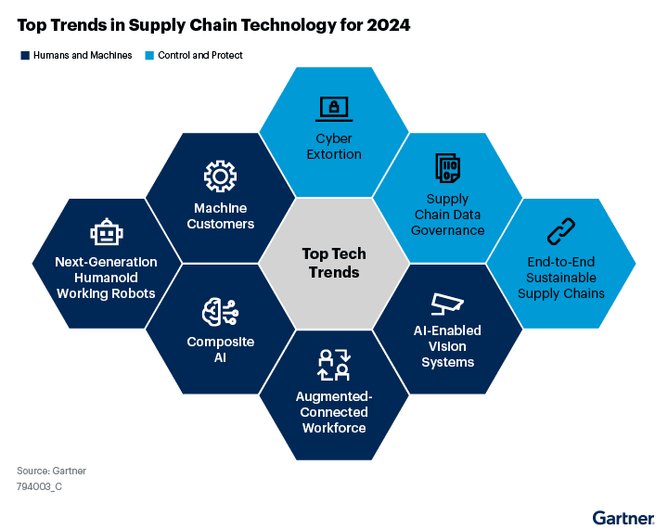

With that in mind, the research and consulting giant has identified eight strategic supply chain technology trends for 2024 that will surely aid leaders in pursuit of their objectives.

“This year’s trends are driven by themes that encourage supply chain technology leaders to ensure their foundation can support both past and future investments, while also looking ahead for new differentiation opportunities,” explains Christian Titze, VP Analyst in Gartner’s Supply Chain Practice.

“AI variants continue to be a driver of trends, such as in robotics.”

Gartner's top eight trends for 2024

Gartner says this year’s supply chain tech trends were driven by two broad themes: the need for supply chain leaders to leverage emerging technologies to control and protect their businesses; and new opportunities for competitive differentiation through the complementary integration of humans and machines.

The eight trends are as follows:

Cyber extortion

Cyber criminals are highly successful when it comes to executing ransomware attacks to extort funds from supply chain organisations. It’s highly likely they will harness the power of AI to generate advanced attack tools, making their attacks even more effective. Gartner experts say supply chain technology leaders should collaborate with IT leadership to confirm ransomware attack scenarios are included in the corporate risk management processes and develop a detailed ransomware incident response playbook.

Supply chain data governance

The emergence of powerful tools for advanced analytics and AI techniques is massively scaling the capabilities for cross-functional visibility, scenario modelling and decision automation. As those technologies are increasingly adopted, the importance of maintaining a high level of data quality and strict governance process is becoming business mission critical.

End-to-end sustainable supply chains

Sustainability-related legislation is growing globally, driving a shift from voluntary to mandatory compliance. As a result, the accuracy of sustainability data must be uplifted from indicator to investment grade, thus meeting stakeholder requirements while also driving internal decision making.

AI-enabled vision systems

AI-enabled vision systems are novel hyper-automation solutions that combine industrial 3D cameras, computer vision software and advanced AI pattern recognition technologies. These solutions can autonomously capture, interpret, and make inferences based on the unstructured images the vision systems see in real-time.

Augmented connected workforce

Augmented connected workforce (ACWF) initiatives reduce the time required after onboarding for an employee to become fully productive and improve their decision making. Gartner describes the ACWF as a strategy to optimise the value derived from a human worker by establishing a connective tissue that brings together intelligent technology, workforce analytics and skills augmentation. It treats these capabilities as a unified, cohesive strategy to accelerate and scale talent.

Composite AI

Composite AI is defined as the combined application of multiple AI techniques to improve the efficiency and accuracy of learning, broaden the level of knowledge representations and solve a variety of business problems that drive supply chain performance improvements. Depending on the context of a specific use case, Gartner highlights that different AI techniques—or more often a combination of techniques—will make more sense than relying on a one-size-fits-all approach.

Next-generation humanoid working robots

Next-generation humanoid robots “combine sensory awareness with mobile manipulation and dynamic locomotion” to perform productive work that was previously carried out by humans. These robots will typically imitate the human body with a head that has sensors and cameras for sensing its environment; a body that houses the power and mechanicals; arms and hands for grasping, manipulating and carrying items; and legs for dynamic locomotion.

Machine customers

Machine customers are non-human economic actors that autonomously obtain goods or services in exchange for payment. Examples include: IoT-connected devices or assets that place orders independently of a human command; intelligent replenishment algorithms that maintain availability of consumables; and intelligent assistants that suggest deals to consumers.

******

Check out the latest edition of Supply Chain Magazine and sign up to our global conference series – Procurement and SupplyChain LIVE 2024.

******

Supply Chain Digital is a BizClik brand.

- How the C3 AI Supply Chain Suite Drives Increased ResilienceTechnology

- The Art of Supply Chain Planning with Gartner, SAP, KinaxisSupply Chain Risk Management

- How to Boost Supply Chain Visibility with Tive and ArvatoSupply Chain Risk Management

- Top 100 Women 2024: Stephanie Rankin Smith – No. 8Operations