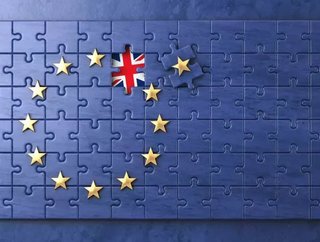

Food supply chains at risk in event of 'cliff edge Brexit'

Fragile food supply chains are at major risk if the UK fails to secure a Brexit deal, according to the British Retail Consortium (BRC).

The group has written to UK Prime Minister Theresa May and the European Union’s Chief Brexit Negotiator Michel Barnier to highlight the potential for damaging consequences for millions of UK consumers and tens of thousands of EU-based producers if an agreement in the Brexit negotiations is not reached that protects the free flow of goods between the EU and UK from 29 March 2019.

A third of the food consumed in the UK is imported from the EU.

In a statement, BR said: “Our letter highlights how the UK’s highly complex food supply chain – and the excellent value and choice it offers UK consumers – depends upon frictionless trade with the EU. The livelihoods of tens of thousands of farmers and food producers in the EU also depend on it.

“This supply chain is fragile. Failure to reach a Brexit deal – the cliff edge scenario – will mean new border controls and multiple ‘non-tariff barriers’ through regulatory checks, creating delays, waste and failed deliveries.

This could lead to dramatic consequences, with food rotting at ports, reducing choice and quality for UK consumers. It could also lead to higher prices as the cost of importing goods from the EU increases. And in the EU, £21 billion of exports to the UK are at stake.”

SEE ALSO:

Commenting on it, Richard Pennycook, Chairman of the British Retail Consortium said: “We must avoid a cliff edge scenario on the 29 March 2019 at all costs. Failure to achieve a smooth transition will create a lose-lose scenario for UK consumers and EU producers. Our food supply chain is complex, highly organised and ultimately fragile.

“Frictionless trade is essential if the industry is to continue to provide the level of choice and value in shops that UK consumers are used to seeing. It is now of the utmost importance that the UK Government proposes a workable solution to the backstop that gets the Withdrawal Agreement over the line and allows for a smooth transition.

“We need the EU to be flexible and creative in negotiation and recognise what is at stake for exports to the UK. Time is running out.”

KEY FACTS

• 50% of Britain’s food is imported and of that 60% comes from the EU-27.

• In 2016 3.6 million containers from the European Union passed through UK ports, just under 10,000 per day, delivering 50,000 tonnes of food to UK consumers.

• Salad leaves can be picked and loaded onto lorries in Spain on a Monday, delivered to UK stores on a Thursday and still have 5 days’ shelf life.

• BRC analysis finds that food and beverage products would face an average increase in the cost of importing from the EU of up to 29% from non-tariff barriers, under a no-deal scenario.

• BRC figures estimate that more than 12,500 small retail businesses will be at high risk of going bust in the event of no deal.

- How the C3 AI Supply Chain Suite Drives Increased ResilienceTechnology

- The Art of Supply Chain Planning with Gartner, SAP, KinaxisSupply Chain Risk Management

- Top 100 Women 2024: Stephanie Rankin Smith – No. 8Operations

- Why SAP Supply Chain Solutions Could Transform ManufacturingTechnology