Nokia: Putting 5G at the Heart of Connected Logistics

Nokia is undoubtedly a leader in the 4G and 5G private wireless market, supporting enterprises in their quest for digitalisation and automation.

This allows them to reap the benefits of Industry 4.0, resulting in a more sustainable, safe and efficient method of fast production and transportation of goods.

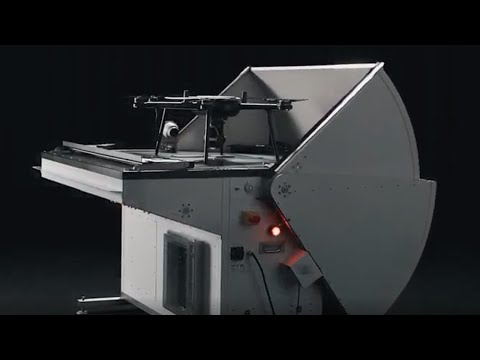

Nokia continues to help customers accelerate and simplify industrial digitalisation, including through the utilisation of its mission-critical industrial edge called MXIE, private wireless, Wi-Fi industrials, routers, dongles and even drones – all the devices required to connect people and machines.

In addition, it is providing a wide range of its own and third-party industrial applications to introduce remote control robots, digital workers, digital twin, drone-based analytics and much more.

Leading the charge in this space is Nokia’s Enterprise Campus Edge Business, which works with an array of technologies including private wireless, the industrial edge, devices and applications.

All these solutions help to simplify digitalisation for manufacturing and logistics hubs that want to benefit from Industry 4.0.s

“We help customers simplify and accelerate their digital transformation by pre-integrating all these ingredients,” says David de Lancellotti, Vice President of Enterprise Campus Edge Business. “This means they don’t have to worry about coordinating multiple suppliers and they can speed up their time-to-market and time-to-value significantly.

“We see that 80% of our customers get their ROI from their digitalisation investment within six months, which is huge. We work with a wide ecosystem of partners to make this even simpler and customise any requirements customers might have.”

How 5G private wireless supports automation

Poor network connectivity is hitting logistics hard – particularly when it comes to warehousing.

Research from the Association of British Insurers (ABI) projects that the logistics market in Europe will lose more than €1bn (US$1.08bn) in revenue throughout 2024 due to inadequate connectivity.

While Wi-Fi has a role to play here, highly-automated logistics hubs and warehouses require a mission-critical wireless connectivity layer – like 5G private wireless – to support the high level of automation and mobility required.

David highlights one of Nokia’s own customers, which has no fewer than 50 picking robots in a single micro-fulfilment centre (MFC). He explains that 5G private wireless and an industrial edge offer the low latency and high bandwidth required for a highly-automated MFC with hundreds of picking robots and AGVs.

“Addressing this issue requires a shift to more advanced and reliable connectivity solutions designed specifically for small premises, delivering deterministic and reliable private wireless network connectivity,” David continues.

“This solution is scalable, easy to deploy and requires zero upfront investment, making it a pragmatic choice for SMEs – including those in the logistics sector.”

One of Nokia’s latest innovations is a compact version of its private wireless solution, provided as a three-year subscription service, including the hardware. This allows for fast deployment, is more cost-efficient than Wi-Fi and reduces energy use while providing better performance.

“There’s still room for Wi-Fi when connecting IT applications,” David goes on, “but for highly-automated warehouses there must be an additional layer of mission-critical 5G connectivity. We can even combine the two layers, so Wi-Fi can work as a back-up or even augment capacity.”

Reduced costs and increased productivity

David is unequivocal in his belief that 5G private wireless connectivity has the potential to revolutionise the logistics industry, enabling an up to 25% increase in cycle time for mobile robots or autonomous guided vehicles (AGVs) and a 60% reduction in energy consumption and related costs.

It facilitates seamless handover of AGVs between access points, latency reduction and real-time asset tracking throughout the supply chain, vastly improving efficiency and productivity.

What’s more, given the capacity of 5G is much higher than Wi-Fi, new use cases and applications can be deployed. For example, a video-based drone network to assess stock or identify issues requires a lot of bandwidth, which private wireless and an industrial edge can provide.

Overall, the benefits of 5G in logistics are well documented.

David references Nokia research which found almost three-quarters of early adopters of 5G and industrial edge saw a reduction in their operating costs of at least 10%, while a similar proportion experienced a more than 10% increase in productivity.

This comes as little surprise given autonomous robots and sensors connected via 5G networks can optimise and speed up goods movement, reduce waste and enhance overall site management.

David points to Graybar, a Nokia customer and leading North American distributor of electrical communications and data networks, as an example of a company improving outcomes thanks to wireless connectivity.

“Poor Wi-Fi signals used to stop their operations which was detrimental for their business, but now they have flawless connectivity everywhere,” David concludes.

“It gives them enhanced speeds, better connectivity and happier employees as their pickers and packers can continue their work without interruption.”

******

Check out the latest edition of Supply Chain Magazine and sign up to our global conference series – Procurement and SupplyChain LIVE 2024.

******

Supply Chain Digital is a BizClik brand.