Cold chain logistics 'flying blind' - Tive & FreightWaves

Cold chain logistics is a $700 billion market and yet many shippers still lack control of cold chain shipments, a new report says.

The cold supply chain is the lifecycle of a temperature-sensitive product, from manufacturing and packaging, through to distribution and point of purchase.

The cold chain keeps goods fit for purpose and consumption and prevents waste. Products requiring cold chain solutions include pharmaceuticals, vaccines, biologics, lab samples, diagnostic materials, chemicals, food, and beverages.

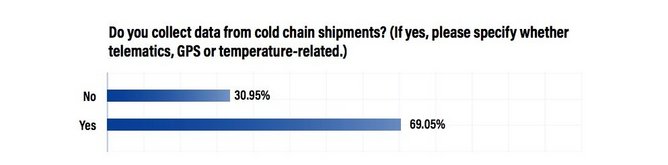

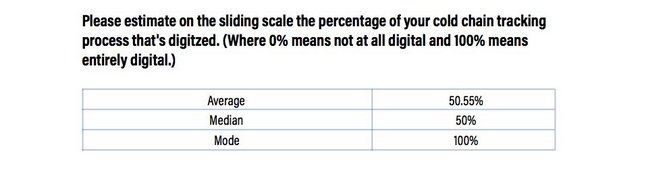

Temperature disruptions, poor timing, and improper positioning of goods all wreak havoc on refrigerated shipments, and this makes data collection and real-time visibility vital for protecting shipment health.

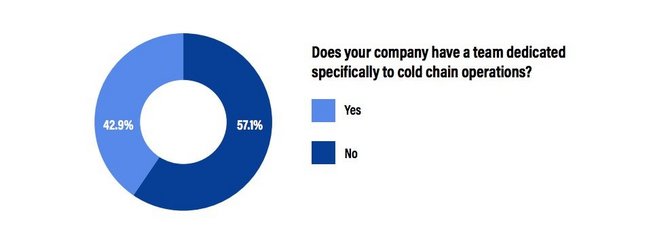

Yet new research – called Tracking the Cold Chain – shows that barely half (57%) of companies that deal in perishable goods have a team dedicated to cold chain operations.

The study was a joint effort from FreightWaves – a provider of global supply chain market intelligence – and also supply chain visibility specialist, Tive.

The companies teamed up to learn more about how supply chain decision makers collect and utilise data from their cold chain operations.

Only half of cold-chain shippers employ specialists

The study shows that – even though cold chain operations are among the most important daily shipments – many do not have a dedicated team monitoring these loads.

This, say the authors, suggests that cold chain shipments are handled by a single team at most companies.

Where a dedicated cold chain team does exist, the most common headcount is three, the report reveals. Both Freightwaves and Tive recognise that, for smaller companies, it might be impractical to employ cold chain-specific teams, but adds that, nevertheless, the benefits of having cold chain specialists “should not be underestimated”.

The authors say that choosing high-quality partners to help track and manage cold chain shipments is important for all shippers but is “essential for those who lack a specialised team to handle such shipments”.

Below are graphics from the report detailing its headline findings.