Political unrest causing supply chain problems - SAP survey

A new SAP survey finds that many senior business decision-makers expect supply chain disruptions to run until well into 2023.

One in three says the issues will last until the end of summer 2023. More than half (52%) think their supply chain still needs much improvement, while 49% expect issues to last through the end of 2022.

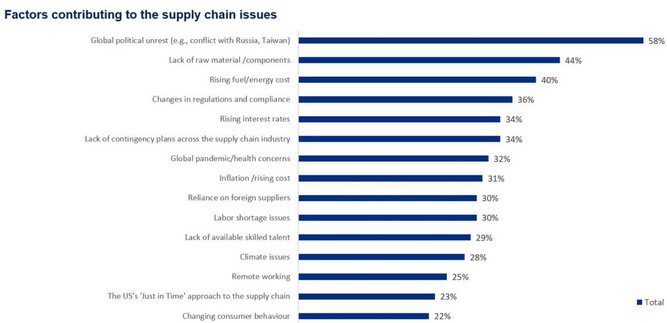

Business leaders told SAP that current supply chain issues primarily stem from global political unrest (58%), lack of raw materials (44%) and rising fuel and energy costs (40%). Only 31% cited inflation as a major contributor.

Looking ahead, the top three supply chain disruptions business leaders expect in 2023 are:

- Reduced availability of raw materials in the United States (50%)

- A slowdown in construction of new homes (44%)

- Disruption to public transport due to lack of drivers (44%)

Lost pandemic revenue still issue for companies

In order to cover the extra costs of supply chain issues, more business leaders say they’ve had to turn to wage or recruitment freezes (61%) and staff job cuts (50%). Only 41% have chosen to increase the price of their products or services.

Regarding the upcoming holiday season, 73% of business leaders expect an increase in e-commerce volume this season compared to last year. To sell their own products, they plan to differentiate around:

- Speed of delivery (64%)

- Excellence of customer service (57%)

- Availability of products (52%)

- Sustainability credentials (47%)

- Price reductions (42%)

- Companies Are Fortifying Supply Chains for the Future

Every organisation said their supply chain needs improving to some extent, and that they’re making big changes to prepare for future disruptions and to fortify their supply chains. Business leaders plan to:

- Adopt new technology to overcome challenges (74%)

- Implement new contingency measures (67%)

- Find new environmentally friendly supply chain solutions (58%)

Many firms moving away from just-in-time supply

Nearly two in three companies (64%) are moving from a ‘just in time’ supply chain to a ‘just in case model by increasing the amount of inventory they store.

“The move to just-in-case means organisations will be storing more inventory to help meet customer demand, but doing so also means increased cost,” said Scott Russell, Member of the Executive Board of SAP Customer Success.

He added: “Managing the supply chain is a constant balancing act. Over the past couple of decades, the just-in-time approach traded resilience for efficiency and lower costs, which in turn made the supply chain fragile.

“Still, cost remains a factor, especially in the current economic environment. Technology can help organisations strike the right balance by enabling more real-time collaboration between trading partners.”