BASF develop breakthrough compostable snack packaging

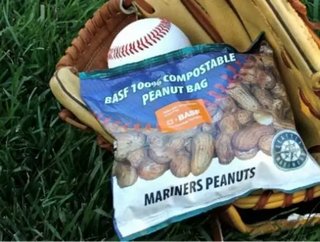

Chemical giant BASF has developed a new sustainable snack packaging from a material which is 100 percent compostable, using biopolymers to provide a viable alternative to traditional materials.

“Flexible packaging with this BASF technology is a big step forward for the snack food industry,” said Kimberley Schiltz, Market Development Manager Consumer Packaging, BASF. “It means that popular snack foods can be brought to market in compostable packaging that delivers needed shelf-life at a competitive price point, with a more sustainable ‘end-of-life’ solution than with conventional packaging materials.”

SEE RELATED STORIES FROM THE WDM CONTENT NETWORK:

- Park Logistics take gold in Olympic bid

- Make the move to green without moving your warehouse

- The world's largest gantry crane arrives in Brazil

To launch their new innovation, BASF are teaming up with The Seattle Mariners, one of the greenest teams in Major League Baseball. The Mariners are supporting the launch of the new material by partnering with BASF to give away 10,000 bags of peanuts in compostable packaging to fans arriving to see the Mariners take on the Boston Red Sox at the Safeco Field.

A member of the Green Sports Alliance, The Seattle Mariners’ aggressive zero-waste goals make the Safeco Field a natural place for BASF to introduce this new sustainable snack packaging to the American public. This season, the team is on track to divert 85% of its waste from landfills, up from just 12% in 2006.

Mariners VP of Operations, Scott Jenkins, has his sights set on 90% diversion, but closing the gap has proven to be an elusive goal. “All of our service ware is already compostable, but snack food bags have been one of the biggest barriers preventing us from getting to our goal,” said Jenkins. “Flexible packaging made with BASF biopolymers could represent the holy grail of greening for our waste stream.”

Major breakthroughs in sustainability like BASF’s new materials must balance economic and environmental interests in order to become a viable green alternative.

However, according to Jenkins the new material could actually save money. “Whenever there are contaminants in our compost stream, like regular snack bags and candy wrappers, we have to pay a premium to have them removed by hand. If all of the snacks sold at Safeco came in compostable packaging, it would represent a significant savings of time and money for the team and get us a whole lot closer to achieving zero waste.”

- Who is Dr Christoph Wegner, new head of Information Services and Supply Chain operations at BASF?Digital Supply Chain

- BASF to sell global textile chemicals business to ArchromaProcurement

- Save Energy in Your Warehouse to Meet Green InitiativesSupply Chain Risk Management

- Make the move to green without moving your warehouseSupply Chain Risk Management