Solving the automation challenge for manufacturers with K3 Syspro

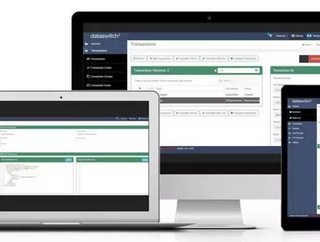

A purpose built systems integration and data manipulation tool, enabling business to become more efficient through automating processes, has been released by K3 Syspro.

With only eight percent of manufacturers having a significant understanding of Industry 4.0 process, and 64 percent of these looking towards automation software, the release of Dataswitch comes at the right time.

Cathie Hall, Managing Director of K3 Syspro, said: “There is a lot of technology already implemented into manufacturing and businesses are generally good at recognising there is a need for new systems, and implementing them. The problem is that many businesses are doing this at the point of need, rather than stepping back and looking at their overall technology strategy. The result is a number of disparate systems that automate certain areas of the supply chain, but which do not communicate or integrate with each other for complete automation.

“DataSwitch solves this problem by enabling businesses to communicate and integrate various business systems, setting up unique work streams from one single source. It fills the integration gap that many manufacturing businesses are missing, and can empower people to automate without the need for any technical skills.”

Dataswitch harnesses the Internet of Things to integrate front-office and back-office management and production systems, to help manufacturing businesses better manage, utilise and analyse the data available to them.

Supply Chain Digital's August issue is now live.

Follow @SupplyChainD on Twitter.