Electronic Presentment & Payment in supplychain finance

Written by Oliver Belin, (pictured, right) author of Supply Chain Finance Solutions: Relevance – Propositions – Market Value and Business Development Executive with PrimeRevenue, a leader in supply chain finance

Supply chain finance (SCF) and electronic invoicing are not new concepts, but they have certainly made a big splash within the corporate finance pool as a way to reduce costs in the supply chain and optimize working capital. Integrating SCF solutions with e-invoicing has caused a shift in the marketplace because competition is no longer between one company and another, but among the stake holders across the entire supply chains.

The need for companies to protect their precious supply chains is becoming more of a concern with the environmental disruptions that affect the logistical supply chain as well as the impact credit market paralysis caused by the economic crisis. Combining the benefits of SCF and e-invoicing has been a game changing strategic adaptation within the market environment for preserving the value in the supply chain under the current fragile state of the economy.

The Rules Have Changed

Businesses and more recently governments worldwide are increasingly turning to electronic invoice presentment and payment (EIPP) solutions to enhance information and financial flows within corporate supply chains. Associated payments can take many forms, encompassing retail payments, FX and securities settlements, bank-to-bank transfers, remittances and other cross-border payments. Business-to business (B2B) payments in particular depend upon significant information flows between suppliers and buyers, however, these information flows cannot be efficiently facilitated through the narrow bandwidth electronic funds transfer (EFT) systems provided by banks.

Optimizing the Flow of Financial Information

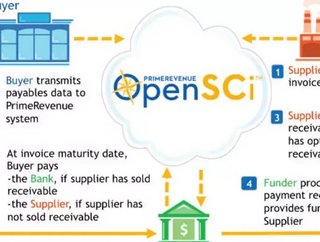

In response to this capabilities gap, corporations are focusing on EIPP solutions to optimize the flow of financial information within corporate supply chains. These solutions integrate payment systems with accounting systems which hold accounts receivable (A/R) and accounts payable information (A/P) and facilitate the transmission of integrated payments and remittance information. This provides a valuable foundation upon which working capital optimization solutions such as Supply Chain Finance can be implemented. The continuing evolution of payments convergence and the development and adaptation of EIPP has also been widely recognized as a key enabler in reducing processing time and financial labor in today’s supply chain.

From Paper to Electronic Settlements

Paper based payments are moving towards electronic settlements and mobile payments are on the rise. Through the integration of e-payment and invoice approval workflow in their settlement process companies can enhance operational efficiencies, reduce cycle time for invoice approval through payment, and enhance the information and financial flows within the supply chain. Wider adoption of EIPP solutions is increasingly being driven by the working capital optimization opportunities offered by SCF providers such as PrimeRevenue. The effectiveness of SCF solutions in optimizing working capital within corporate supply chains is significantly enhanced by the more efficient invoice approval processes achieved through EIPP.

Prevalence of Electronic Payment and Invoicing in Supply Chain Finance

The global supply chain and enhanced focus on process optimization increases the importance of e-payments. The business case for the prevalence of EIPP solutions is co-active, the move from paper-based to electronic payments is happening today. There is a critical mass of business transactions dematerialized and available in electronic format feeding Supply Chain Finance services. Companies are taking a second look at EIPP as they begin to evaluate long-term efficiencies for their financial supply chain.

EIPP as the New Standard in the Virtual World

More and more e-business stakeholders (customers, suppliers, policy makers, etc.) will favor organizations and businesses that make their virtual transactions easy to manage and maintain, as well as safeguard their information zealously. Just as computerized banking altered the financial horizon about a decade ago, EIPP is establishing a new norm in virtual commerce. Far from being just an emerging trend in the industry, electronic payment and invoicing is on the fast track to becoming the standard and preferred way of doing business in the virtual world. Companies who recognize this will reap the financial benefits and earn the loyalty of virtual consumers all over the world.

Whether among the brick and mortar stores or in the virtual marketplace, competition drives business, and innovation is the fuel of competition. As more and more industries establish their virtual presence and engage their public exclusively along online marketplaces, the system that recognizes and supports this reality is the system that will survive and take the lead. EIPP solutions are clearly proving to be an integral part of a successful Supply Chain Finance platform.

About Oliver Belin

As Business Development Executive with PrimeRevenue, Oliver Belin works with strategic partners to strengthen and expand the value delivered to the organization’s world-class client base. Prior Oliver worked for leading institutions in SCF. In 2008, Oliver founded Swiss Commercial Capital, a company specialized in trade finance solutions, which was acquired by Macquarie Bank. In 2011, he released the book “Supply Chain Finance Solutions”, published by Springer Verlag.