Tracking our packages with ParceLive from Hanhaa

Hanhaa, the IOT innovator, will soon be rolling out its ParceLive device and monitoring system.

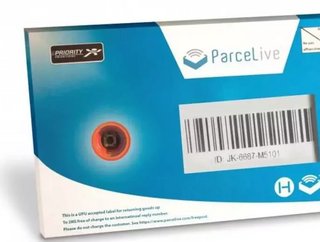

Designed for tracking high-value, fragile, and time- or temperature-sensitive packages, ParceLive is a postcard-sized device that is inserted into a parcel at the point of distribution. By monitoring several key factors, the device allows both sender and receiver to monitor the exact location and condition of their package in real-time.

Here at Supply Chain Digital, we were kindly invited to give it a try.

“The ParceLive technology fits our long-term objective of bringing value-adding digital services into the packaging industry, which we refer to as the ‘Internet of packaging’,” said Anders Persson, Managing Director at BillerudKorsnäs Venture. “ParceLive also addresses sustainability concerns in a way that support BillerudKorsnäs' strategy of challenging conventional packaging for a sustainable future.”

Through the ParceLive online portal, we were able to track where our parcel was at any point during delivery. The server updates the feed every 20 minutes with new information on its location.

A bit like tracking Santa at Christmas.

Beyond highly accurate GPS tracking, ParceLive also tracks and records the temperature and humidity experienced by a parcel, an accelerometer identifies if it has been dropped, and light detection tells the monitoring system when the parcel has been opened.

Following a series of successful pilots, which we can happily confirm now includes us here at Supply Chain Digital, ParceLive is entering public engagements with logistics companies including Sigma Retail Solutions and Avarto Bertelsmann; just two of a growing network of partners that serve some of the world’s most-recognized brands.

The first wave of the rollout will involve 500 ParceLive devices tracking real parcels on their journeys across the world. The company is on track to produce 20,000 units for general availability by mid-2017.

And the best bit?

This:

Whoops! No, that was payment from Hanhaa for us to write about ParceLive.

The best bit, is the tracking device itself.

The device is letterbox size and nice and light - it will not be bulking out parcels anytime soon!

With a quick push of that button and then simply pop it in the letterbox and the device will work its way back to sender.

And if you're worried it won't get there?

Well, simply login and track it.

ParceLive’s deployment follows a successful pilot with partner Arvato Bertelsmann, which manages the return of ParceLive devices (sent back by the parcel recipient) in addition to using the system for its own clients’ parcel tracking.

The industry rollout will be officially launched on January 30th at a snazzy event at Hanhaa’s London headquarters, where attendees will be able to see the results of the ParcelLive pilots and learn how the disruptive technology addresses growing industry challenges with a bundle of new innovations.

The January issue of Supply Chain Digital is live!

Follow @SupplyChainD on Twitter.